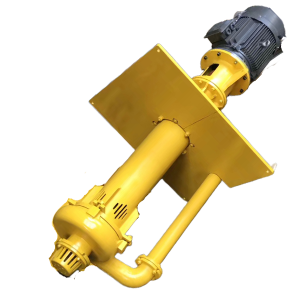

Thekofatso ea theko e theko e tlaase ea Castel Slurry Pump Covery Pum

E leng e nang le moea o motle le o tsoelang pele khafetsa oa boleng ba lihlahisoa tsa bareki o khutlisa boleng ba lihlahisoa tsa boleng bo phahameng bakeng sa polokeho, ts'ehetso ea tikoloho le puisano e tšepahalang ea tikoloho le puisano e tšepahalang. Amohela metsoalle eohle e haufi ho beha ho reka ha liteko bakeng sa ho etsa maikutlo a malelele a maikutlo a khoebo a khoebo.

E nang le moea o motle le o tsoelang pele khafetsa o ntlafatsa boleng ba rona ba lihlahisoa ho fihlela litakatso tsa bareki ho fihlela sepheo, ho ts'epahala, ho ts'epahala, tikoloho le ho ts'epahala, tikoloho le ho ts'epahalaChina hasfely Slurry pompo ea pompo le pompo, Ho ba bareki ba tsoang linaheng tse fetang 20 'me botumo ba rona bo amohetsoe ke bareki ba rona ba hlomphuoang. Ntlafatso e sa feleng le ho lelekisa bofokoli ba 0% ke melaoana ea rona ea mantlha ea boleng. U tšoanela ho uena u batla letho, u se ke ua tsilatsila ho ikopanya le rona.

Likarolo tsa Pump tsa Slurryli kopantsoe le a ah / hh / m slump Tsamaiso e tsoetseng pele ea lihlahisoa tsa lihlahisoa tsa ho etsa.

Li-slurry li-dirops tse ikhethileng

Ho feto-fetoha ha Ahr ka mokhoa o phethahetseng ho ahr, h

Khoutu ea Lisebelisoa: A03, A04, A05, A07, A07, A45, A49, A59, A59, A59, A59, A59, A69

Khoutu ea lisebelisoa tsa rabara: R08, R24, R26, R33, R38, R55, R66

√Synthetic rubber materials code:S01,S10,S12,S21,S31,S42,S44,S50

Khoutu ea lisebelisoa tsa lisebelisoa: U01, U05

Setšoantšo sa √shaft: 45 #, 403, SS304, SS316

Lintho tse fumanehang tsa Sleeve: SS410, SS420 SS320, SS316

√ Anlan

Ho hlorisetsa lintho tsa bolulo / ho ba le thepa ea ho qetela: G01, D21

√

√packing: q05

Tlhaloso e tloaelehileng ea lisebelisoa

Tšepe:

• Kmtbcr27 ke tšepe e tšoeu e nang le ts'ebetso e ntle ea maemo a mangata.

• Kktbrcr28 ke tšepe e tšoeu ea Martsine e nang le mesebetsi e mebe ea 430 e nang le bothata ba li-430 ho tsoa ho Prinsion.

• Kktbr35 ke khoho ea premium / li-corrosion tsa chrome

Lisebelisoa tse hlophisitsoeng:

Pump e lula e etsa boiteko bo tsoelang pele ea thepa e kang tšepe, hypalon, henferol

Likopi tsa PUP tsa Slurry

Meining e boima | Ts'ebetso ea liminerale | Ho etsa lintho tse ngata | Ho Ts'oarella Piperive | Likopo tsa NPSH | Opereishene e tsoelang pele (Snore) Sump3 Slump

Hlokomela:

* Likarolo tsa pompo tsa pompo ea li-slurry li sa fetole feela ka likarolo tsa ntoa tsa warman®Slurry.E leng e nang le moea o motle le o tsoelang pele khafetsa oa boleng ba lihlahisoa tsa bareki o khutlisa boleng ba lihlahisoa tsa boleng bo phahameng bakeng sa polokeho, ts'ehetso ea tikoloho le puisano e tšepahalang ea tikoloho le puisano e tšepahalang. Amohela metsoalle eohle e haufi ho beha ho reka ha liteko bakeng sa ho etsa maikutlo a malelele a maikutlo a khoebo a khoebo.

Theko ea theko e tlase eaChina hasfely Slurry pompo ea pompo le pompo, Ho ba bareki ba tsoang linaheng tse fetang 20 'me botumo ba rona bo amohetsoe ke bareki ba rona ba hlomphuoang. Ntlafatso e sa feleng le ho lelekisa bofokoli ba 0% ke melaoana ea rona ea mantlha ea boleng. U tšoanela ho uena u batla letho, u se ke ua tsilatsila ho ikopanya le rona.

Th Iss e nang le Thre, e otlolohileng

| Khoutu ea Boitsebiso | Tlhaloso ea lintho tse bonahalang | Likarolo tsa Kopo |

| A05 | 23% -30% ea tšepe e tšoeu | Empeller, li-morance, thetso, e lla |

| A07 | 14% -18% ea tšepe e tšoeu | Keper, li-liners |

| A49 | 27% -29% Kr lock e tšoeu ea carbon | Keper, li-liners |

| A33 | 33% ea likhopo tsa khatiso | Keper, li-liners |

| R55 | Rabara ea tlhaho | Keper, li-liners |

| R33 | Rabara ea tlhaho | Keper, li-liners |

| R26 | Rabara ea tlhaho | Keper, li-liners |

| R08 | Rabara ea tlhaho | Keper, li-liners |

| U01 | Polyurethane | Keper, li-liners |

| G01 | Iron e putsoa | Frame poleiti, sekoaelo sa poleiti, theleightse, lelera, moaho oa ho roala ntlo, motheo |

| D21 | Ducusley Iron | Polasetiki ea Frame, sekoaelo sa poleiti, ho tsamaea ka ntlo, motheo |

| E05 | Carbon Sense | Shaft |

| C21 | Tšepe e se nang thuso, 4cr13 | Shaft Speeve, Lantern Loy |

| C22 | Tšepe e se nang thuso, 304ss | Shaft Speeve, Lantern Loy |

| C23 | Tšepe e se nang thuso, 316ss | Shaft Speeve, Lantern Loy |

| S21 | Buyl rabara | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S01 | Rabara ea EPDM | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S10 | Nitrile | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S31 | Hypalon | Empeller, liners, selikalikoe, thetso, e kopaneng le litiiso tse kopaneng, litiiso tse kopaneng |

| S44 / K S42 | Neoprene | Empeller, liners, li-mehele tse kopaneng, litiiso tse kopaneng |

| S50 | Vinete | Li-mehele tse kopaneng, litiiso tse kopaneng |