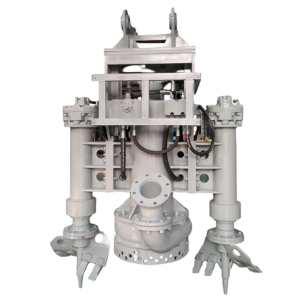

Leqephe la theko bakeng la H14110 CroMe Slurry Pomp Volite Laer bakeng sa 16/14 Tu-ah

Ho phehella ka "boleng bo phahameng, ho tsamaisoa ka potlako, re thehile ts'ebelisano ea nako e telele le ho fumana lihlahisoa tsa theko e lekanang le ea bahoebi ho fana ka lihlahisoa tsa boleng bo holimo le ts'ebeletso e kholo. Ka mofuthu o amohela ka mofuthu ho tla ba le rona, a re ho bokelle ho hotle, ho fofa.

Ho phehella "boleng bo holimoChina slurry pompo le vor, Re fana ka ts'ebeletso ea omp ea tlhokomeliso ea litlhoko tsa hau le litlhoko tsa hau tse khethehileng. Ka sehlopha se matla sa baenjineri ba nang le boiphihlelo ho Desiger le nts'etsopele, re nka monyetla o mong le o mong oa ho fana ka lihlahisoa le tharollo ho bareki ba rona.

Likarolo tsa Pump tsa Slurryli kopantsoe le a ah / hh / m slump Tsamaiso e tsoetseng pele ea lihlahisoa tsa lihlahisoa tsa ho etsa.

Li-slurry li-dirops tse ikhethileng

Ho feto-fetoha ha Ahr ka mokhoa o phethahetseng ho ahr, h

Khoutu ea Lisebelisoa: A03, A04, A05, A07, A07, A45, A49, A59, A59, A59, A59, A59, A69

Khoutu ea lisebelisoa tsa rabara: R08, R24, R26, R33, R38, R55, R66

√Synthetic rubber materials code:S01,S10,S12,S21,S31,S42,S44,S50

Khoutu ea lisebelisoa tsa lisebelisoa: U01, U05

Setšoantšo sa √shaft: 45 #, 403, SS304, SS316

Lintho tse fumanehang tsa Sleeve: SS410, SS420 SS320, SS316

√ Anlan

Ho hlorisetsa lintho tsa bolulo / ho ba le thepa ea ho qetela: G01, D21

√

√packing: q05

Tlhaloso e tloaelehileng ea lisebelisoa

Tšepe:

• Kmtbcr27 ke tšepe e tšoeu e nang le ts'ebetso e ntle ea maemo a mangata.

• Kktbrcr28 ke tšepe e tšoeu ea Martsine e nang le mesebetsi e mebe ea 430 e nang le bothata ba li-430 ho tsoa ho Prinsion.

• Kktbr35 ke khoho ea premium / li-corrosion tsa chrome

Lisebelisoa tse hlophisitsoeng:

Pump e lula e etsa boiteko bo tsoelang pele ea thepa e kang tšepe, hypalon, henferol

Likopi tsa PUP tsa Slurry

Meining e boima | Ts'ebetso ea liminerale | Ho etsa lintho tse ngata | Ho Ts'oarella Piperive | Likopo tsa NPSH | Opereishene e tsoelang pele (Snore) Sump3 Slump

Hlokomela:

* Likarolo tsa pompo tsa pompo ea li-slurry li sa fetole feela ka likarolo tsa ntoa tsa warman®Slurry.Ho phehella ka "boleng bo phahameng, ho tsamaisoa ka potlako, re thehile ts'ebelisano ea nako e telele le ho fumana lihlahisoa tsa theko e lekanang le ea bahoebi ho fana ka lihlahisoa tsa boleng bo holimo le ts'ebeletso e kholo. Ka mofuthu o amohela ka mofuthu ho tla ba le rona, a re ho bokelle ho hotle, ho fofa.

Pampiri ea theko bakeng saChina slurry pompo le vor, Re fana ka ts'ebeletso ea omp ea tlhokomeliso ea litlhoko tsa hau le litlhoko tsa hau tse khethehileng. Ka sehlopha se matla sa baenjineri ba nang le boiphihlelo ho Desiger le nts'etsopele, re nka monyetla o mong le o mong oa ho fana ka lihlahisoa le tharollo ho bareki ba rona.

Th Iss e nang le Thre, e otlolohileng

| Khoutu ea Boitsebiso | Tlhaloso ea lintho tse bonahalang | Likarolo tsa Kopo |

| A05 | 23% -30% ea tšepe e tšoeu | Empeller, li-morance, thetso, e lla |

| A07 | 14% -18% ea tšepe e tšoeu | Keper, li-liners |

| A49 | 27% -29% Kr lock e tšoeu ea carbon | Keper, li-liners |

| A33 | 33% ea likhopo tsa khatiso | Keper, li-liners |

| R55 | Rabara ea tlhaho | Keper, li-liners |

| R33 | Rabara ea tlhaho | Keper, li-liners |

| R26 | Rabara ea tlhaho | Keper, li-liners |

| R08 | Rabara ea tlhaho | Keper, li-liners |

| U01 | Polyurethane | Keper, li-liners |

| G01 | Iron e putsoa | Frame poleiti, sekoaelo sa poleiti, theleightse, lelera, moaho oa ho roala ntlo, motheo |

| D21 | Ducusley Iron | Polasetiki ea Frame, sekoaelo sa poleiti, ho tsamaea ka ntlo, motheo |

| E05 | Carbon Sense | Shaft |

| C21 | Tšepe e se nang thuso, 4cr13 | Shaft Speeve, Lantern Loy |

| C22 | Tšepe e se nang thuso, 304ss | Shaft Speeve, Lantern Loy |

| C23 | Tšepe e se nang thuso, 316ss | Shaft Speeve, Lantern Loy |

| S21 | Buyl rabara | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S01 | Rabara ea EPDM | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S10 | Nitrile | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S31 | Hypalon | Empeller, liners, selikalikoe, thetso, e kopaneng le litiiso tse kopaneng, litiiso tse kopaneng |

| S44 / K S42 | Neoprene | Empeller, liners, li-mehele tse kopaneng, litiiso tse kopaneng |

| S50 | Vinete | Li-mehele tse kopaneng, litiiso tse kopaneng |