Tp / popr verry e boreleli

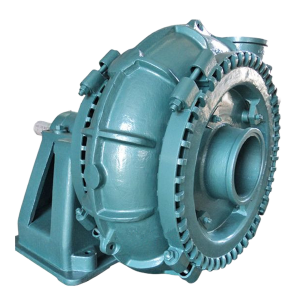

Tp / popr verry e borelelie etselitsoe likopo tse hlokang ho tšepahala ho hoholo le ho se khone ho ts'epahala ho feta literompeta tsa ts'ebetso e tloaelehileng li ka fana ka tlhahiso. E nang le elattomer e koahetsoeng kapa e behiloe ka thata. Ha ho na likotoana tse kenelletseng kapa ho paka. Boqapi bo holimo habeli. Ho hlophisoa ha bolelele ba bolelele le Suctator e fumanehang. PUP ea hau ea TSP / ORPR e loketse ho tsamaisa lino tse boima tsa ho hlorisa le li-slurid tse matlafatsang le li-sluries tse kenellang ka kakaretso kapa likoting.

Litšobotsi tsa moralo

√ apesa le ho feta, sekhomaretsi se fokolang

Metsoako e kolobisitsoeng e fumaneha ka mefuta e fapaneng ea li-slloys le esele e tsoang ho tsitsipano e kholo ea ho hanyetsa.

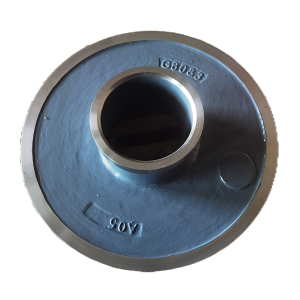

• abrassion ahlanyetsi a a05 ultrachrome® alloy.

• abrasion / Corsuon-e hatellang A49 Hyperchrome®

• Mehala e ke keng ea lekanngoa.

• Li-elalastomers tsa tlhaho le tsa maiketsetso.

Ha ho na liphoso tse benyang

Shaft ea porole e qoba ho hloka tlhokahalo e ka tlase - eo hangata e leng mohloli oa ho teneha pele ho nako.

• Likarolo tse boima tsa mela e boima, kaholimo ho ho hloa.

• Ha ho na likopo tse koahetsoeng.

• Labyrinth / Flinger a Beaver.

• Shaft e kholo, shaft e kholo.

Ha ho na mathata a ho qotsa

Moralo oa Smartical Slitler ha o hloke tiiso ea shaft.

√ ha ho na ntho e hlokahalang

Moralo oa topoto o holimo le o tlase o loketse maemo a "Snore".

√ kotsi e fokolang ea ho thibela

Likamore tse hlophisitsoeng tse hlophisitsoeng le litemana tse kholo tsa sebopeho li fokotsa kotsi ea li-blockrages.

√ Zero Onecillary ea metsi

Moralo o hlakileng o sa utloahaleng o se nang likhoele kapa meqolo e batang e qobang tlhokahalo ea likhoele tse theko e phahameng kapa tse behang metsi a bilikang.

Tp / tspiPompo ea ho slurry e otlolohilenglitekanyetso tsa ts'ebetso

| Mohlala | Ho tsamaisana le matla a p (kw) | Bokhoni Q (m3 / h) | Hlooho H (m) | Lebelo n (R / MIN) | EFF.PER (%) | Mohlomphehi da. (mm) | Max.Partorinction (mm) | Boima (kg) |

| 40PV-TLSP (R) | 1.1-15 | 7.2-29 | 4-28.5 | 1000-2200 | 40 | 188 | 12 | 300 |

| 65QV-TLSP (R) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

| 100rv-TLSP (R) | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | 370 | 32 | 920 |

| 150SV-TLSS (R) | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

| 200sv-rusv (r) | 15-110 | 180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | 2800 |

| 250tv-TLSS (R) | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| 300TV-TLSS (R) | 22-200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

Tp / tspiPompo ea ho slurry e otlolohilengspeations

Lipula tsa TSP / tsa tsp è li fumaneha libakeng tse ngata tse tloaelehileng ho lumellana le lits'ebetso tse pompa haholo. Lipulumo tsa TSP / tseo Ts'ebetso ea PSP / ORPS e nang le tšepe e thata

* TSP TRISTY LIPPPS LE LITLHAKU TSE BONAHANG KE LITS'A LITSELA TSE KHOLO TSA WARMAN® BEPS LE SPRES.

Th Iss e nang le Thre, e otlolohileng

| Khoutu ea Boitsebiso | Tlhaloso ea lintho tse bonahalang | Likarolo tsa Kopo |

| A05 | 23% -30% ea tšepe e tšoeu | Empeller, li-morance, thetso, e lla |

| A07 | 14% -18% ea tšepe e tšoeu | Keper, li-liners |

| A49 | 27% -29% Kr lock e tšoeu ea carbon | Keper, li-liners |

| A33 | 33% ea likhopo tsa khatiso | Keper, li-liners |

| R55 | Rabara ea tlhaho | Keper, li-liners |

| R33 | Rabara ea tlhaho | Keper, li-liners |

| R26 | Rabara ea tlhaho | Keper, li-liners |

| R08 | Rabara ea tlhaho | Keper, li-liners |

| U01 | Polyurethane | Keper, li-liners |

| G01 | Iron e putsoa | Frame poleiti, sekoaelo sa poleiti, theleightse, lelera, moaho oa ho roala ntlo, motheo |

| D21 | Ducusley Iron | Polasetiki ea Frame, sekoaelo sa poleiti, ho tsamaea ka ntlo, motheo |

| E05 | Carbon Sense | Shaft |

| C21 | Tšepe e se nang thuso, 4cr13 | Shaft Speeve, Lantern Loy |

| C22 | Tšepe e se nang thuso, 304ss | Shaft Speeve, Lantern Loy |

| C23 | Tšepe e se nang thuso, 316ss | Shaft Speeve, Lantern Loy |

| S21 | Buyl rabara | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S01 | Rabara ea EPDM | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S10 | Nitrile | Li-mehele tse kopaneng, litiiso tse kopaneng |

| S31 | Hypalon | Empeller, liners, selikalikoe, thetso, e kopaneng le litiiso tse kopaneng, litiiso tse kopaneng |

| S44 / K S42 | Neoprene | Empeller, liners, li-mehele tse kopaneng, litiiso tse kopaneng |

| S50 | Vinete | Li-mehele tse kopaneng, litiiso tse kopaneng |