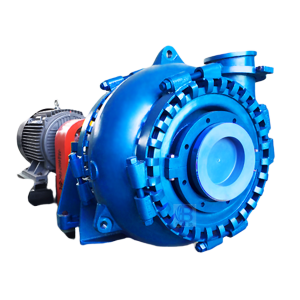

pompo ea TSP/TSPR e otlolohileng ea slurry

pompo ea TSP/TSPR e otlolohileng ea slurrye etselitsoe lits'ebetso tse hlokang ho ts'epahala le ho tšoarella ho feta lipompo tse tloaelehileng tse otlolohileng tse ka fanang ka tsona.Elastomer e kentsoeng ka botlalo kapa tšepe e thata e kentsoeng.Ha ho li-bearings tse qoeletseng kapa ho paka.Moetso o phahameng oa ho hula habeli.Bolelele ba ho qoelisoa bo ikhethileng le mochini oa ho hula o teng.The TSP/TSPR vertical sump pump e loketse hantle bakeng sa ho sebetsana ka thata le lino tse runyang le tse senyang le li-slurries ha li qoelisoa ka har'a lipompo kapa likoting.

Likarolo tsa Moqapi

√ Ho se khathatse ho hoholo, ho hola ho fokolang

Likarolo tse kolobisitsoeng li fumaneha ka mefuta e mengata e fapaneng ea li-alloys le li-elastomers, moo Weir Minerals e khethang motsoako o nepahetseng oa lisebelisoa bakeng sa ho hanyetsa ka ho fetesisa hoo e batlang e le ts'ebeliso efe kapa efe ea indasteri, ho kenyeletsoa le tse hlokang ho hanyetsa ho hoholo le ho kutu, le moo likaroloana tse kholo kapa li-slurries tse phahameng haholo. kopana.

• Alloy ea A05 Ultrachrome® e hanyetsanang le abrasion.

• Alloy ea A49 Hyperchrome® e hanyetsanang le maqeba/ho bola.

• Litšepe tse sa hloekang tse sa jeng.

• Li-elastomer tsa tlhaho le tsa maiketsetso.

√ Ha ho na bofokoli ba ho jara ka metsing

The robust cantilever shaft e qoba tlhokahalo ea li-bearings tse ka tlaase ho metsi - tseo hangata e leng mohloli oa ho hlōleha ho beha pele ho nako.

• Boima ba lirolara, ka holim'a mountingplate.

• Ha ho li-bearings tse ka tlas'a metsi.

• Tšireletso e nang le Labyrinth / flinger.

• Shaft e thata, e bophara bo boholo.

√ Ha ho na mathata a ho tiisa shaft

Moralo o otlolohileng oa cantilever ha o hloke tiiso ea shaft.

√ Ha ho hlokahale hore ho behoe lintho pele

Moqapi o kenang ka holimo le o ka tlase o loketse maemo a "snore".

√ Ho fokotsa kotsi ea ho thibela

Li-inlets tse sirelelitsoeng le litselana tse kholo tsa li-impeller li fokotsa kotsi ea ho thibela.

√ Litšenyehelo tse tlatselletsang tsa metsi ha li na letho

Moralo o otlolohileng oa cantilever o se nang tšoelesa kapa li-bearings tse ka tlas'a metsi o qoba tlhoko ea tšoelesa e theko e phahameng kapa e nang le metsi a phallang.

TSP/TSPRPompo e Emeng ea Slurrys Mekhahlelo ea Ts'ebetso

| Mohlala | Matla a tšoanang P (kw) | Bokhoni Q (m3/h) | Hlooho H (m) | Lebelo n (r/mots) | Eff.η (%) | Impeller dia. (mm) | Max.likaroloana (mm) | Boima ba 'mele (kg) |

| 40PV-TSP(R) | 1.1-15 | 7.2-29 | 4-28,5 | 1000-2200 | 40 | 188 | 12 | 300 |

| 65QV-TSP(R) | 3-30 | 18-113 | 5-31.5 | 700-1500 | 60 | 280 | 15 | 500 |

| 100RV-TSP(R) | 5.5-75 | 40-289 | 5-36 | 500-1200 | 62 | 370 | 32 | 920 |

| 150SV-TSP(R) | 11-110 | 108-576 | 8.5-40 | 500-1000 | 52 | 450 | 45 | 1737 |

| 200SV-TSP(R) | 15-110 | 180-890 | 6.5-37 | 400-850 | 64 | 520 | 65 | 2800 |

| 250TV-TSP(R) | 18.5-200 | 261-1089 | 7-33.5 | 400-750 | 60 | 575 | 65 | 3700 |

| 300TV-TSP(R) | 22–200 | 288-1267 | 6-33 | 350-700 | 50 | 610 | 65 | 3940 |

TSP/TSPRPompo e Emeng ea Slurrys Likopo

Lipompompe tsa TSP/TSPR verrical slurry li fumaneha ka mefuta e mengata e fapaneng ea boholo bo tloaelehileng ho lumellana le lisebelisoa tse ngata tsa ho pompa.Lipompo tsa sump tsa TSP/TSPR li paka ho ts'epahala le ts'ebetso ea tsona lefats'eng ka bophara ho: ts'ebetso ea liminerale, ho lokisa mashala, ts'ebetso ea lik'hemik'hale, ho ts'oaroa ha litšila, lehlabathe le lehlohlojane le hoo e batlang e le tanka e 'ngoe le e 'ngoe, sekoti kapa boemo ba ho sebetsana le sekoti fatše.Moralo oa pompo oa TSP/TSPR o nang le tšepe e thata (TSP) kapa elastomer e koahetsoeng (TSPR) e etsa hore e be e loketseng bakeng sa li-slurries tse senyang le / kapa tse senyang, boholo ba likaroloana tse kholo, li-slurries tse phahameng haholo, ts'ebetso e tsoelang pele kapa ea "snore", mesebetsi e boima e hlokang cantilever. lithapo.

* Lipompo tsa slurry tsa TSP tse otlolohileng le li-slurry li ka fapanyetsanoa feela le lipompo le li-slurry tse otlolohileng tsa Warman® SP.

TH Cantilevered, Horizontal, Centrifugal Slurry Pump Material:

| Khoutu ea lintho tse bonahalang | Tlhaloso ea Lintho | Lisebelisoa tsa Kopo |

| A05 | 23% -30% Cr White Iron | Impeller, liner, expeller, expeller ring, stuffing box, throatbush, frame plate liner insert |

| A07 | 14%-18% Cr White Iron | Impeller, li-liner |

| A49 | 27%-29% Cr Low Carbon White iron | Impeller, li-liner |

| A33 | 33% Cr Erosions & Corrosion Resistance Iron White | Impeller, li-liner |

| R55 | Rabara ea Tlhaho | Impeller, li-liner |

| R33 | Rabara ea Tlhaho | Impeller, li-liner |

| R26 | Rabara ea Tlhaho | Impeller, li-liner |

| R08 | Rabara ea Tlhaho | Impeller, li-liner |

| U01 | Polyurethane | Impeller, li-liner |

| G01 | Tšepe e Bohlooho | Letlapa la foreime, letlapa la sekoaelo, moleka, lesale la ho leleka, ntlo e behang, setsi |

| D21 | Tšepe ea Ductile | Letlapa la foreimi, letlapa le koahelang, ntlo e behang, setsi |

| E05 | Tšepe ea Carbon | Shaft |

| C21 | Tšepe e se nang tšepe, 4Cr13 | Mokotla oa letsoho, selikalikoe sa lantern, restrictor ea lebone, selikalikoe sa molala, bolt ea tšoelesa |

| C22 | Tšepe e sa hloekang, 304SS | Mokotla oa letsoho, selikalikoe sa lantern, restrictor ea lebone, selikalikoe sa molala, bolt ea tšoelesa |

| C23 | Tšepe e sa hloekang, 316SS | Mokotla oa letsoho, selikalikoe sa lantern, restrictor ea lebone, selikalikoe sa molala, bolt ea tšoelesa |

| S21 | Butyl Rubber | Mehele e kopantsoeng, litiiso tse kopanetsoeng |

| S01 | EPDM Rabara | Mehele e kopantsoeng, litiiso tse kopanetsoeng |

| S10 | Nitrile | Mehele e kopantsoeng, litiiso tse kopanetsoeng |

| S31 | Hypalon | Impeller, li-liners, lesale la ho leleka, lelekang, mehele e kopaneng, litiiso tse kopaneng |

| S44/K S42 | Neoprene | Impeller, liner, Mehele e kopaneng, litiiso tse kopaneng |

| S50 | Viton | Mehele e kopantsoeng, litiiso tse kopanetsoeng |